CERAMENT BONE VOID FILLER is an injectable, moldable and drillable synthetic bone void filler consisting of 40% hydroxyapatite, 60% calcium sulfate and the radio-contrast agent iohexol.

The unique ratio of hydroxyapatite and calcium sulfate is designed to enable CERAMENT to resorb at the same rate that bone forms. Calcium sulfate acts as a resorbable carrier for hydroxyapatite, and hydroxyapatite is highly osteoconductive, promoting bone ingrowth.

The characteristics of CERAMENT BONE VOID FILLER make it ideal for minimally invasive surgery and open procedures where bone remodeling is required.

Remodels into host bone within 6-12 months

With CERAMENT, simultaneous de novo bone formation is seen throughout the material and it is fully remodeled into host bone within 6-12 months. Rapid bone remodeling reduces the risk of fracture, non-union and (re)infection.

Injectable and flowable

CERAMENT can be injected through a 16G needle, making it ideal for minimally invasive procedures. Injectability is enhanced by the shape of the hydroxyapatite (HA) particles, enhancing flow and enabling injection to be performed without the need for high pressure.

Flowability ensures excellent spread into and around a bone defect. This is particularly important for complex defects, where the extent of bone loss may not be apparent at first and certain areas may be difficult to access.

Added radiopacity

Hydroxyapatite (HA) and calcium sulfate (CaS) are naturally radiopaque, but in CERAMENT BONE VOID FILLER radiopacity is enhanced by a liquid component called C-TRU®, consisting of the radiopaque agent iohexol.

This allows for the precise application of CERAMENT as it is easy to visualize under fluoroscopy.

Isothermic and not affected by room temperature

CERAMENT does not create heat during setting, so there is no risk of thermal injury to tissues.

Setting time and handling properties are consistent and reliable irrespective of the temperature of the operating room (OR).

CERAMENT is also conveniently stored at room temperature.

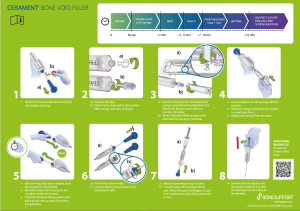

Easy to mix and use

The pre-filled, sterile, mixing and injection device ensures hassle-free preparation and delivery. The mixing device is simple to use and helps to achieve a homogenous paste, enhances rheology (flow characteristics) and reduces waiting time prior to application. It also reduces the risk of contamination, and there are no toxic or unpleasant fumes.

CERAMENT BVF

CERAMENT BONE VOID FILLER Mixing Chart

CERAMENT BONE VOID FILLER Product Fact Sheet

CERAMENT BONE VOID FILLER Mixing Video

Instructions for use

Request previous version of the Instructions for Use here